How does it work?

I2C to CAN Click as its foundation uses the LT3960, I2C to CAN-Physical transceiver used to send and receive I2C data up to 400kbps using the CAN-Physical layer for differential signaling over twisted pair connections from Analog Devices. Using two integrated CAN transceivers, the LT3960 creates a differential proxy for each single-ended I2C clock and data signal capable of crossing harsh or noisy environments across two twisted pairs. Each transceiver consists of a transmitter and receiver, capable of quickly converting I2C dominant signal into a differential dominant signal and vice versa. Also, it extends functionality in environments with high common-mode voltages due to electrical noise or local ground potential differences.

I2C to CAN Click communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings, supporting Fast Mode operation with a clock frequency up to 400kHz. The LT3960 provides a mode selection feature selectable via jumper labeled as MODE, where the user can choose between Master or Slave mode of operation. The SHD pin routed to the CS pin of the mikroBUS™ socket is used to put the LT3960 in a low-power Shutdown mode, disabling both the LDO and transceivers and allows selection between Master and Slave modes when enabled.

The selection between Master and Slave mode is performed by positioning the SMD jumper labeled as MODE to an appropriate position marked as SLV and MST. When a jumper is on the MST position, Master mode is selected, and the EN/MODE pin of the LT3960 is tied to a high logic state, while floating this pin, more precisely positioning the SMD jumper to an SLV position, allows the user to select Slave mode of operation.

This Click board™ can operate with both 3.3V and 5V logic voltage levels selected via the VCC SEL jumper. It allows for both 3.3V and 5V capable MCUs to use the I2C communication lines properly. Additionally, there is a possibility for the LT3960 power supply selection via jumper labeled as VIN SEL to supply the LT3960 from an external power supply terminal in the range from 4 to 60V or with VCC voltage levels from mikroBUS™ power rails. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Specifications

Type

CAN

Applications

Can be used for industrial and automotive networking, remote sensor applications, and more.

On-board modules

LT3960 - I2C to CAN-Physical transceiver used to send and receive I2C data up to 400kbps using the CAN-Physical layer for differential signaling over twisted pair connections from Analog Devices

Key Features

High speed I2C to CAN-physical transceiver, up to 400kbps I2C communications, up to 60V power supply, low current Shutdown mode, and more.

Interface

I2C

Compatibility

mikroBUS

Click board size

M (42.9 x 25.4 mm)

Input Voltage

3.3V or 5V,External

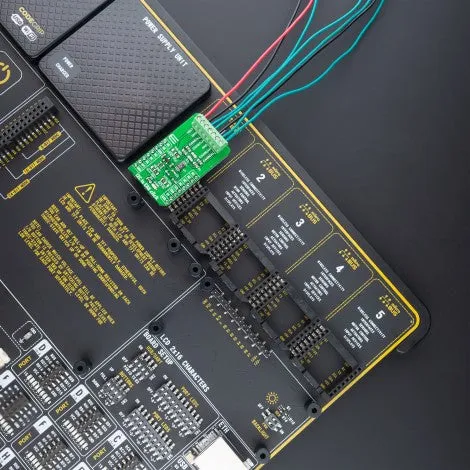

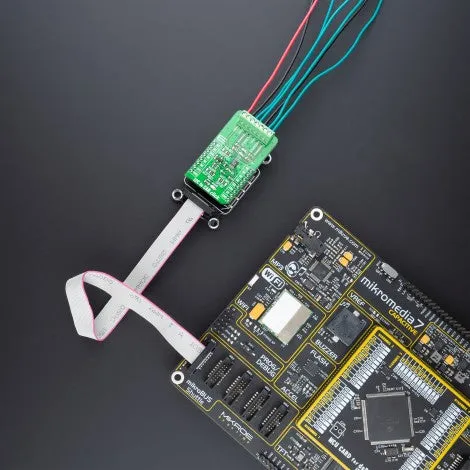

Pinout diagram

This table shows how the pinout on I2C to CAN Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin | Pin | Notes | ||||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| NC | 2 | RST | INT | 15 | NC | ||

| Shutdown | SHD | 3 | CS | RX | 14 | NC | |

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | SCL | I2C Clock | |

| NC | 6 | MOSI | SDA | 11 | SDA | I2C Data | |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | 5V | Power Supply |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| JP1 | VCC SEL | Left | Logic Level Voltage Selection 3V3/5V: Left position 3V3, Right position 5V |

| JP2 | VIN SEL | Right | LT3960 Power Supply Voltage Selection VEXT/VCC: Left position VEXT, Right position VCC |

| JP3 | MODE | Right | Slave/Master Mode Selection SLV/MST: Left position SLV, Right position MST |

I2C to CAN Click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage VCC | 3.3 | - | 5 | V |

| Supply Voltage VIN | 4 | - | 60 | V |

| Data Rate | - | - | 400 | kbps |

| Operating Temperature Range | -40 | 25 | 125 | °C |

Software Support

We provide a library for the I2C to CAN Click as well as a demo application (example), developed using MikroElektronika . The demo can run on all the main MikroElektronika .

Package can be downloaded/installed directly from NECTO Studio Package Manager(recommended way), downloaded from our or found on .

Library Description

This library contains API for I2C to CAN Click driver.

Key functions:

-

i2ctocan_cfg_setup- Config Object Initialization function. -

i2ctocan_init- Initialization function. -

i2ctocan_default_cfg- Click Default Configuration function.

Examples description

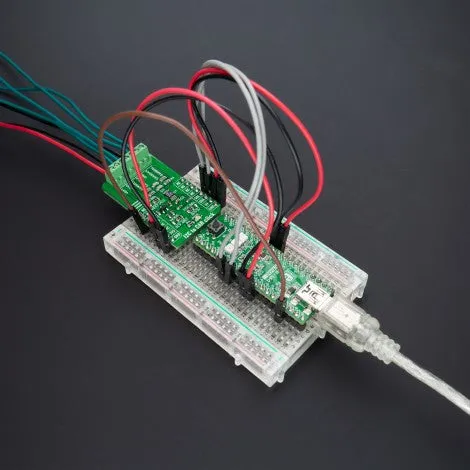

This library contains API for the I2C to CAN Click driver. This demo application shows an example of an I2C to CAN wired to the VAV Press Click for reading differential pressure and temperature measurement.

The demo application is composed of two sections :

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

i2ctocan_cfg_t i2ctocan_cfg; /**< Click config object. */

// Logger initialization.

LOG_MAP_USB_UART( log_cfg );

log_cfg.level = LOG_LEVEL_DEBUG;

log_cfg.baud = 115200;

log_init( &logger, &log_cfg );

log_printf( &logger, "rn" );

log_info( &logger, " Application Init " );

// Click initialization.

i2ctocan_cfg_setup( &i2ctocan_cfg );

I2CTOCAN_MAP_MIKROBUS( i2ctocan_cfg, MIKROBUS_1 );

err_t init_flag = i2ctocan_init( &i2ctocan, &i2ctocan_cfg );

if ( init_flag == I2C_MASTER_ERROR ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

i2ctocan_default_cfg ( &i2ctocan );

log_info( &logger, " Application Task " );

Delay_ms( 100 );

log_printf( &logger, "--------------------------------rn" );

log_printf( &logger, " Set I2C Slave Address rn" );

i2ctocan_set_slave_address ( &i2ctocan, I2CTOCAN_VAV_PRESS_DEV_ADDR );

Delay_ms( 100 );

log_printf( &logger, "--------------------------------rn" );

log_printf( &logger, " Enable Device rn" );

log_printf( &logger, "--------------------------------rn" );

i2ctocan_enable_device( &i2ctocan );

Delay_ms( 100 );

}

The full application code, and ready to use projects can be installed directly from NECTO Studio Package Manager(recommended way), downloaded from our or found on .

Other mikroE Libraries used in the example:

- MikroSDK.Board

- MikroSDK.Log

- Click.I2cToCan

Additional notes and informations

Depending on the development board you are using, you may need , or to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika , or any other terminal application of your choice, can be used to read the message.

mikroSDK

This Click board™ is supported with - MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the and installed for the compiler you are using.

For more information about mikroSDK, visit the .

Cart(

Cart(